Our Testimonials

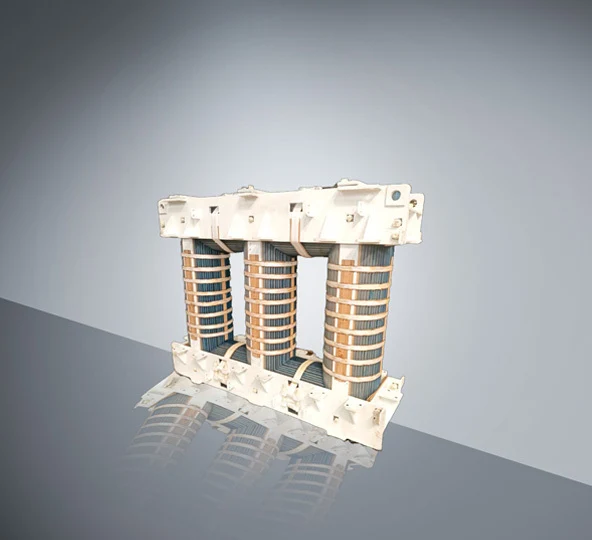

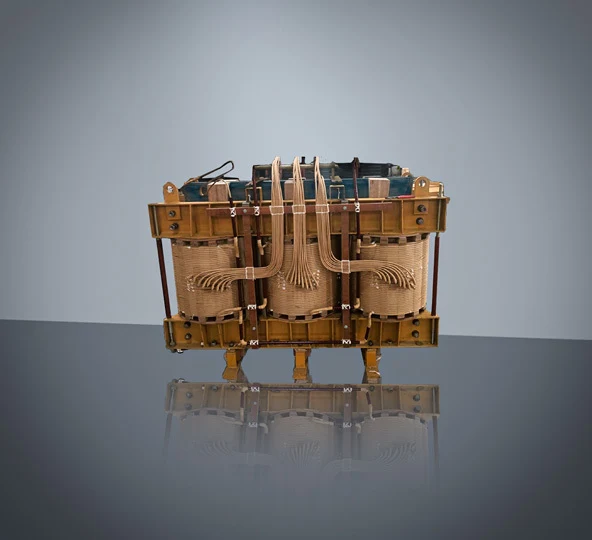

Mangal Electrical Industries has been a trustworthy supplier of our transformer components. Their products, especially the Amorphous Cores, have helped us achieve greater energy efficiency and reduce losses. The technical expertise and support they provide are unmatched, making our collaboration smooth and productive.

Malvika Mishra

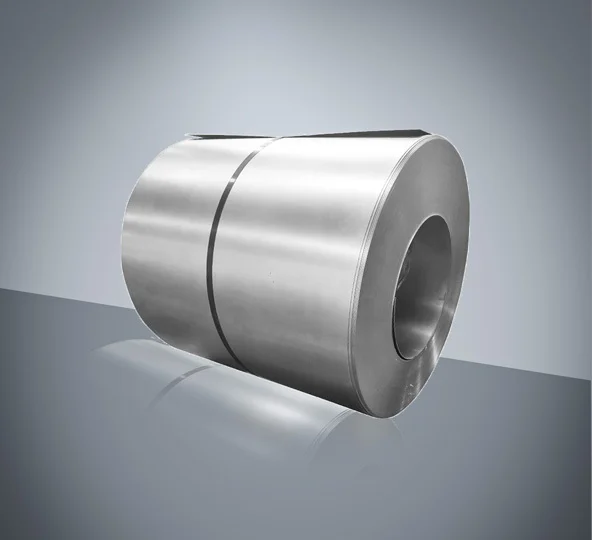

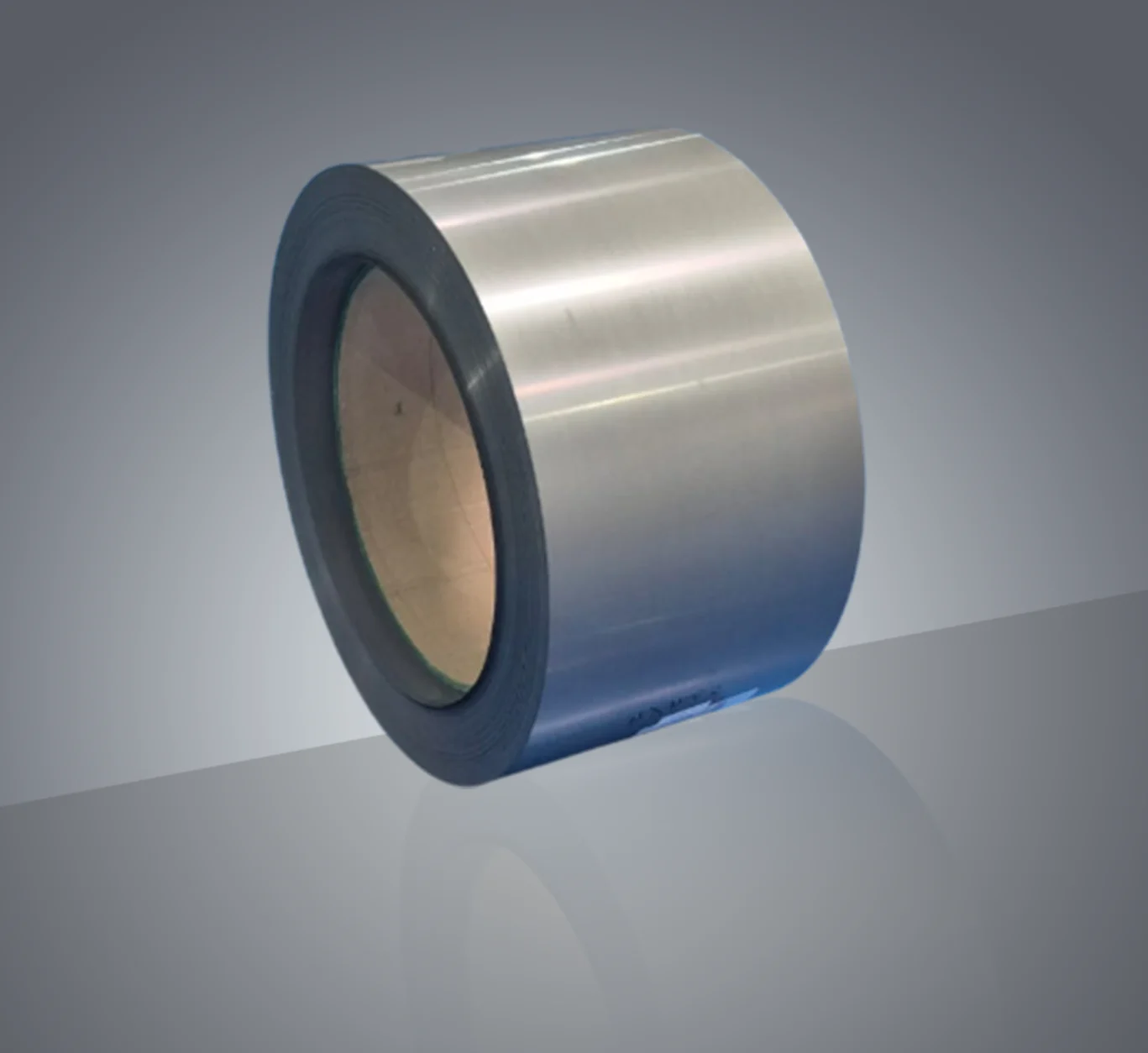

Partnering with MEIL has transformed our operations. Their precision-engineered CRGO Slit Coils and Core Coil Assemblies have set a new standard in quality and performance. The dedication of their team to meet our specific requirements has been remarkable, ensuring the success of our projects.

Kumar Shrivastava

We are satisfied with our partnership with Mangal Electrical. Their advanced manufacturing processes and high-quality products have been crucial in our renewable energy projects. The reliability and efficiency of their transformer components have helped us maintain optimal performance and sustainability.

Gopinath Manorma

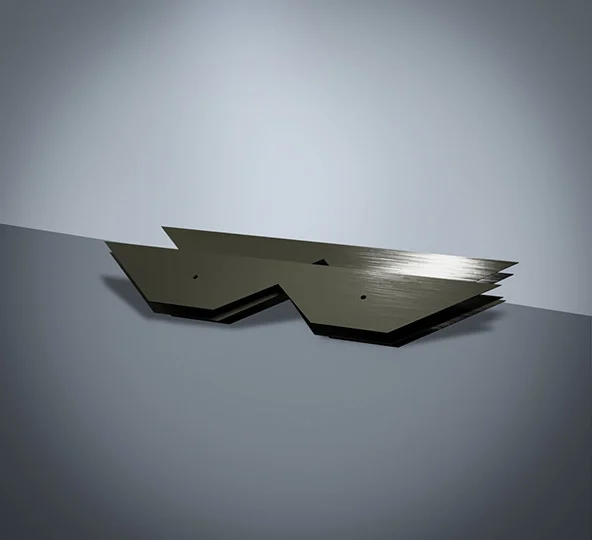

We have been working with Mangal Electrical Industries Ltd. for over a decade, and their commitment to quality and excellence has always impressed us. Their CRGO laminations and core assemblies have significantly enhanced the efficiency and reliability of our transformers. Their team is highly professional and responsive, making them a reliable partner in our projects.

Prem Prakash