Accuracy in Winding ID

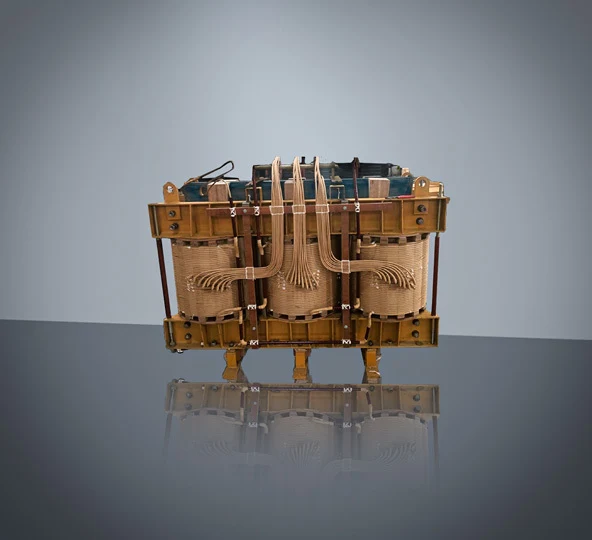

Proper duct placing

Proper material selection and inspection

Bullet points for CCA

MEIPL uses Copper/ Aluminium from a reputed mill for Winding

Focus on using Best Quality insulation

The Winding Process is done by experienced manpower and passed for CCA after serval Quality Checks

Pre-inspection at vendor and incoming stage of all incoming material

All types of tests are performed before tanking and after tanking

We have 6 nos of furnaces to reduce the moisture of the winding and core

A Yokogawa analyser is used to test for accurate results

Insulation resstaivative test perform before tanking and after tanking

Assembly time is highly reduced

Reduction in noise level

Low maintenance and storage cost