Reduces core losses in transformers and increases corrosion

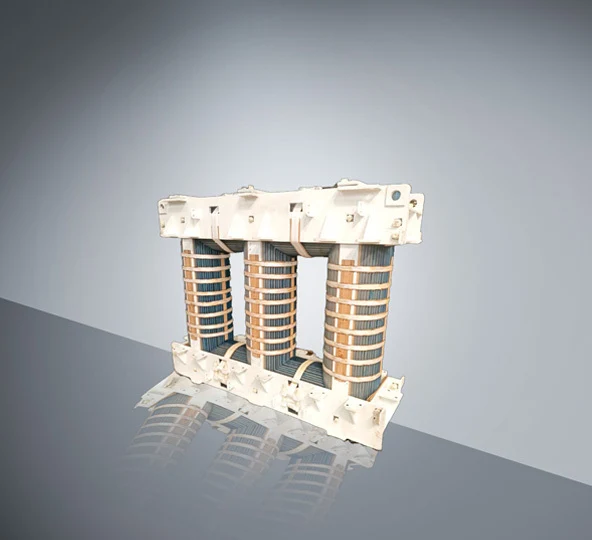

Steplap design to improve building factors as well as productivity

No Load Loss testing

Megar Test

Accuracy in core Dia

Accurate total stack and individual stack

Good quality of insulation

Higher flux density

Noise level reduction

Reduces maintenance and storage cost