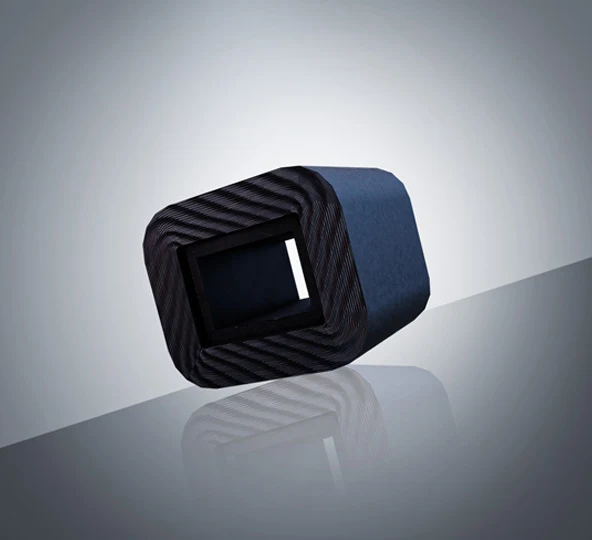

Advanced Technology:

Our wound cores and windings incorporate advanced manufacturing techniques and materials to ensure optimal performance and durability.

Customised Solutions:

We offer customised design solutions to meet the specific requirements of our customers, ensuring compatibility with various voltage levels, frequencies, and power ratings.

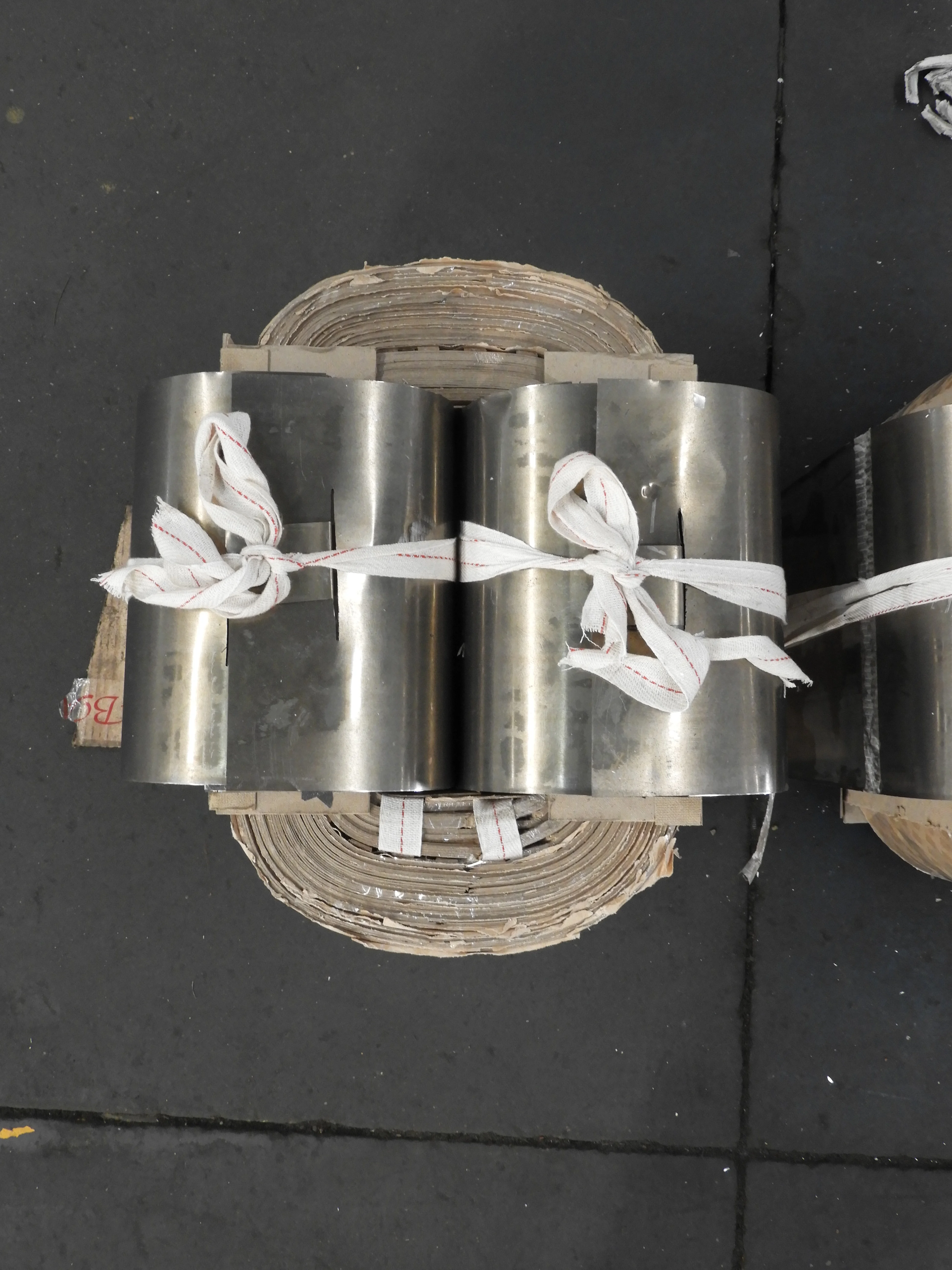

High-Quality Materials:

Our products are built to withstand demanding operating conditions while maintaining exceptional electrical qualities. We achieve this by using premium-grade magnetic core electrical steel.

Efficient Assembly:

Our manufacturing processes are designed for efficiency and precision, resulting in consistent and reliable wound cores and windings that meet industry standards.

Optimised Performance:

Our products are engineered to deliver superior electrical performance and energy efficiency, focusing on minimising core losses, enhancing flux density, and reducing noise levels.

Reliability & Longevity:

Our wound cores and windings are long-lasting, and their durability is guaranteed by strict quality control procedures and testing guidelines.