Blog

Guide to Different Types of Transformer Core Materials

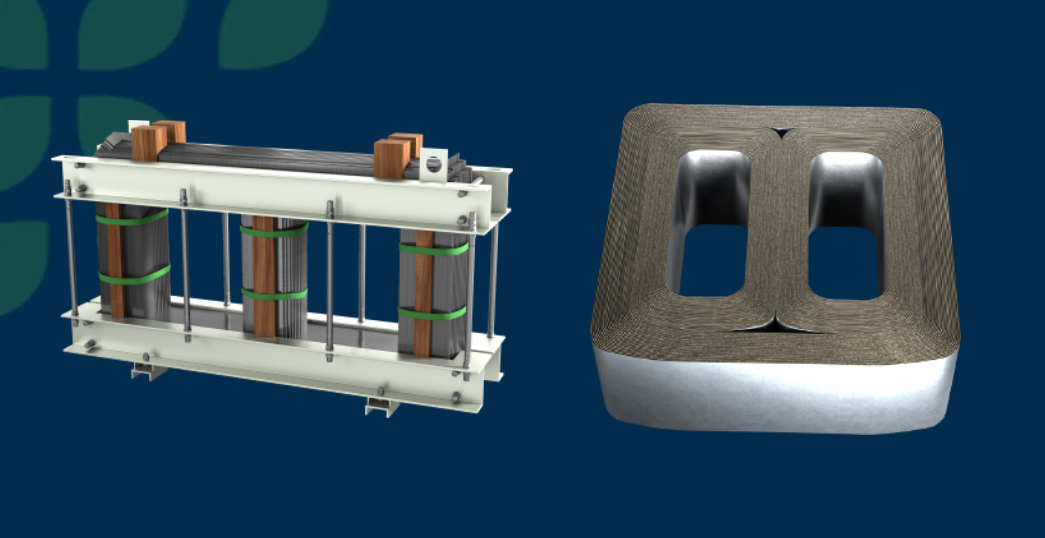

Transformers are a critical component that silently enable electricity to be transferred between two different points efficiently. The core is the heart, and arguably the most critical part of every transformer, which allows easy transfer of energy from one set of coils to the other and minimises energy loss. The transformer core material is a key factor in gauging how well a transformer will perform. This article will take a look at the types of core materials used and how to choose the right one according to specific requirements.

What is a Transformer Core?

A transformer core is the central magnetising element of a transformer that joins the windings together. Its primary function is to establish a controlled path for the magnetic lines of force resulting from the flow of current in the coils. This magnetic flow is what allows the transformer to usher power from a circuit to the next one without a physical tie point. In other words, this core helps make sure electromagnetic induction occurs efficiently.

The core material determines how much energy is lost in the transfer, how much heat is generated, and how large or small the transformer will have to be. The right choice of the core material can improve efficiency, lower operating costs, and improve dependability. In some cases, it can also result in quieter, smoother running. But picking the wrong one can also cause energy loss, overheating and early wear

Properties of Transformer Core Materials

Transformer cores can be functional under different electrical conditions only when they have certain characteristics. Let us dive deeper into the properties of transformer core materials below.

High Permeability Materials

Magnetic permeability is a measure of how readily a material becomes magnetised when exposed to a magnetic field. A high permeability material has an easier time passing magnetic flux, so you do not need to apply extra current to maintain the field. This reduces energy loss directly and increases transformer efficiency. High permeability is particularly significant where efficient magnetic flux transfer is essential.

Electrical Conductivity

Good electrical conductivity is desirable in wires and cables. But it is the opposite for transformer cores. If the core material conducts electricity too well, it leads to circulating currents called eddy currents. These currents waste energy in the form of heat. To minimise this, transformer cores are either made from materials with low conductivity or are laminated to interrupt the path of eddy currents. Laminated silicon steel sheets are a prime example.

Materials with Lower Hysteresis Loss

A little energy is lost on every cycle when the magnetic field in a transformer reverses direction. This is called hysteresis loss. Core materials with a small hysteresis loop will lose less energy when carrying out this process. Such materials ensure not only a higher efficiency but also lower heat release. Fewer cooling systems are required to run them at an optimum temperature.

Durability and Strength Requirements

Transformers typically work in demanding environments. They have to endure vibration, high temperatures and mechanical stress. The core material must be both physically strong and chemically stable to last in the extreme conditions. Durability is everything. It means that as long as the transformer goes through its service life, its safety, reliability and functions are protected. Materials that resist rust, corrosion and will not become deformed are always given a preference.

Common Transformer Core Material Types

Different transformer applications require different materials based on size, frequency, cost, and performance. Below are the most common transformer core material types:

Silicon Steel

Silicon steel is one of the most widely used materials for transformer cores. It is an alloy of iron with 0.5% to 3.5% silicon content. The addition of silicon reduces hysteresis loss and improves electrical resistivity, which helps minimise eddy current losses.

Here are its two types:

Grain-Oriented Silicon Steel

In grain-oriented silicon steel, the grains in the final material are aligned in the rolling direction. This has the effect of greatly enhancing magnetism (in that direction). So it is especially suitable for transformers where magnetic flux is made to flow in a single consistent direction.

Applications:

It is perfect for high-voltage power transformers. They demand efficiency with very minimal energy losses.

Pros:

- Works best when magnetic flux flows in a single, consistent direction

- Very low core losses

- Excellent for directional magnetic flow

Cons:

- Higher cost

- Less suitable for applications with multidirectional flux

Non-Grain-Oriented Silicon Steel

As opposed to grain-oriented, non-grain-oriented silicon steel contains oriented grains at random. This makes it suitable where the direction of the magnetic field changes.

Applications:

Perfect for distribution transformers, rotating equipment, and electric motors.

Pros:

- More affordable

- Versatile and easy to manufacture

- Suitable for alternating flux directions

Cons:

- Higher losses than grain-oriented steel

- Less efficient for high-voltage applications

Amorphous Steel

Amorphous metal consists of a non-crystalline structure, which leads to negligible hysteresis loss. A unique atom arrangement is created by quick cooling so that the atoms are unable to assume a regular position.

Applications:

Ideal for energy-efficient transformers used in power distribution, especially where 24/7 operation is required.

Pros:

- Extremely low core losses

- High efficiency

- Ideal for green energy solutions

Cons:

- Brittle and difficult to shape

- More expensive to produce

Ferrite

Ferrite materials are ceramic compounds consisting of iron oxide mixed with other elements. They are non-metallic and offer high electrical resistivity, making them perfect for high-frequency operations

Applications:

Widely used in switch-mode power supplies, radio-frequency transformers, and electronic circuits. Ferrites are unsuitable for high-power applications due to low saturation flux density.

Pros:

- Very low eddy current losses

- Lightweight and compact

- Ideal for high-frequency applications

Cons:

- Limited magnetic flux capacity

- Can be brittle and fragile

Soft Magnetic Composite (SMC)

SMC materials are made from magnetic powders coated with an insulating layer and compacted into a solid shape. This results in isotropic magnetic properties and excellent eddy current suppression.

Applications:

Used in compact transformer designs, electric motors, and specialised applications requiring quiet and efficient operation.

Pros:

- Excellent 3D magnetic performance

- High mechanical strength

- Low core losses

Cons:

- Limited availability

- It may be costlier than traditional materials

Laminated Cores

Laminated cores are built by stacking thin steel sheets, each insulated from the others. This design reduces eddy current paths and hence decreases energy losses.

Applications:

Used in low and medium-voltage transformers, electric motors, and household appliances.

Pros:

- Reduces eddy current losses

- Cost-effective and widely available

- Good for general-purpose transformers

Cons:

- Bulky in design

- Not suitable for very high-frequency applications

Nanocrystalline Materials

Nanocrystalline materials are advanced core materials made up of very small grains (typically less than 100 nanometres). These offer superior magnetic properties and even lower losses than amorphous steel.

Applications:

Used in high-efficiency and compact transformers in medical equipment, aerospace, and renewable energy systems.

Pros:

- Extremely low hysteresis and eddy current losses

- Excellent thermal stability

- High magnetic saturation

Cons:

- Expensive and complex to produce

- Not yet widely used in all industries due to limited familiarity

How to Choose the Right Transformer Core Material

Selecting the right core material is essential for achieving a balance between performance, cost, and application requirements. Here are the key factors to consider:

Transformer Size and Power Rating

The size and power rating of a transformer greatly influence the core material choice. Large power transformers often use grain-oriented silicon steel or amorphous steel to keep energy losses low. Smaller transformers can use non-grain-oriented steel or ferrites, which are sufficient for lower power needs..

Frequency Range

The operating frequency is another crucial consideration. Materials like ferrites and nanocrystalline alloys are better suited for high-frequency transformers found in telecommunications and power electronics. In contrast, silicon steels are more suitable for low to mid-frequency applications.

Application-Specific Needs

Different environments and functions call for different materials:

- Industrial applications require strong, reliable, and efficient materials like silicon steel or SMC

- Residential transformers prioritise cost-effectiveness, making non-grain-oriented steel a common choice.

- Specialised fields like solar power and electric vehicles benefit from amorphous and nanocrystalline cores due to their low energy loss.

Energy Efficiency Considerations

In applications where energy efficiency is vital, such as in smart grids or green buildings, choosing a core material with minimal hysteresis and eddy losses is important. Although materials like amorphous and nanocrystalline alloys come at a higher initial cost, they lead to long-term energy savings and environmental benefits.

Conclusion

Choosing the proper core material for transformers is essential to achieve the best performance, energy efficiency, and long-term durability. Each material has its unique properties and benefits that offer advantages to various transformer designs and applications. Gaining insight into the characteristics of transformer core materials and how they minimise losses, support various frequencies, and tolerate environmental stress enables engineers and designers to make more effective choices.